|

TLC Trade School invites you to High School Info Night on Wednesday April 12 at 7:00pm.

Tour our campus and learn more about our post-secondary programs in HVAC/R, Welding and Steam Engineering. Staff and instructors will be on site to answer your questions and inform you about: Program Offerings Financial Aid/FAFSA Day and Evening Classes Job Placement and Career Opportunities Students and parents are invited to attend. RSVP to [email protected] or call 508-987-1852

0 Comments

If you're looking for a career that will challenge and reward you, then a career in steam engineering may be right up your alley. Steam engineering is a highly skilled profession that requires an understanding of thermodynamics, fluid dynamics, piping design, and HVAC principles. In this post, we'll take a deeper look at what it takes to become a steam engineer and the different career opportunities available.

What Does it Take to Become a Steam Engineer? Becoming a steam engineer requires specialized education and training. Most positions require some form of post-secondary education or certification in the field. Aspiring steam engineers should consider pursuing degrees in mechanical engineering or related fields like chemical engineering or aeronautical engineering as well as certifications in steam systems. This will give them the foundation necessary for success as well as provide the opportunity to network with experienced professionals in the industry. What are the Different Career Paths Available? Once qualified, there are several different career paths that steam engineers can pursue. They include roles such as power plant operators, boiler engineers, turbine operators, HVAC technicians, process control technicians, and maintenance technicians. These roles require an understanding of thermodynamics and fluid mechanics as well as knowledge of safety procedures and regulations associated with steam systems and boilers. Additionally, many positions require mastery of computer programming and operation of diagnostic equipment to ensure optimal performance of systems. Steam engineering is an exciting field with plenty of rewarding opportunities waiting for those who are willing to put in the work necessary to become successful professionals in the industry. With the right training, dedication, and experience you could have an amazing career working on everything from boilers to turbines! If you're interested in learning more about what it takes to become a steam engineer then consider reaching out to professionals already working in the industry here at TLC. We are conveniently located in Oxford Massachusetts, just minutes form Worcester. Welding is an essential industry that is used in a wide range of applications including the automotive, aerospace, energy, and construction industries. It’s also one of the most important welding technology careers available today. A welding career requires technical abilities as well as knowledge of welding principles and processes.

Welders are responsible for joining two materials together such as metal plates or pipes with welding tools and equipment. They use various welding methods to produce high-quality welds according to safety regulations and structural integrity standards. Welders must be familiar with welding technologies such as gas welding, arc welding, resistance welding, laser welding, soldering, brazing, oxyacetylene welding and more. In addition to creating strong welds, welding technology professionals must also ensure welding processes are safe and efficient. They must understand the welding codes, standards, and regulations that apply to their field of work. Welders should also possess problem solving skills to troubleshoot common welding problems and find solutions quickly. Job opportunities in welding technology can be found in many industries including automotive, construction, energy production, aerospace, shipbuilding, manufacturing and more. These positions require welders to use various welding techniques with varied welding materials such as stainless steel or aluminum alloys. The most common welding career opportunities involve working on offshore platforms and ships. Offshore welding requires a different set of welding tools and techniques since it occurs in a harsh environment surrounded by salt water. Welders must have welding certificates to work offshore and many companies require welding certifications for their welding jobs. Welding technology professionals can also find job opportunities in the automotive industry, where they work on cars, trucks, buses, and other motor vehicles. In this job role welders must understand how welding techniques are used to assemble the different parts of a vehicle. They use various welding tools such as arc welding or resistance welding to fabricate components as well as assemble metal plates and pipes with precision. The aerospace industry is another popular destination for welding technology careers. Aerospace welders typically specialize in working with light alloys such as aluminum and titanium due to their ability to withstand extreme temperatures experienced during space travel. Welders in this sector must be familiar with welding codes and regulations as well as welding principles. Welders are also employed in the energy industry, where they must understand welding technologies such as submerged arc welding, flux cored arc welding, and gas welding to join pipes and vessels used for energy extraction or distribution. They use welding tools such as oxyacetylene torches to form joints between different metal pieces. In conclusion, careers in welding technology are varied and require a range of knowledge and skills. Welders can find job opportunities in many industries from automotive to aerospace and from shipbuilding to energy production. To succeed in these roles welders should have a thorough understanding of welding processes and techniques, possess problem solving abilities, and be familiar with welding codes and safety regulations. Learn more here Careers in Pipefitting

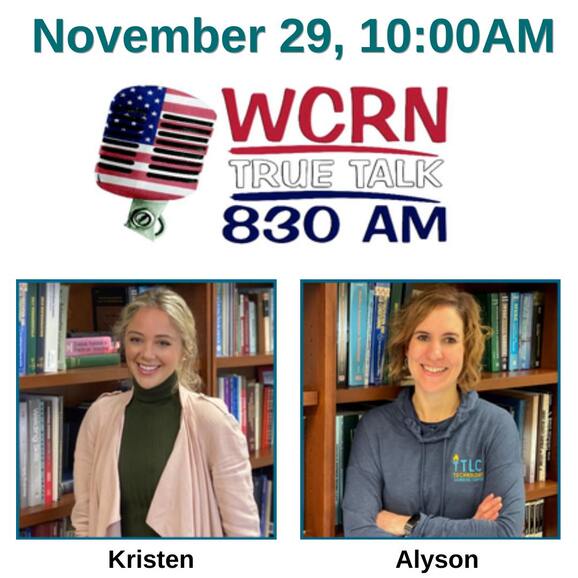

Are you looking for a career in the trades? Consider pipefitting – a profession that is in high demand and provides stable, long-term job security and opportunity. In this blog post, you'll learn what it takes to become a pipefitter and explore some of the potential career paths available. A pipefitter works with pipes, tubes and related components used to convey liquids and gases. They read blueprints or other technical drawings to plan how the pieces should be installed or connected together in order to build plumbing systems, fuel delivery systems, heating systems, medical gas systems and more. Pipefitters must understand the basics of structural engineering so that they can determine which materials are most appropriate for each project. They also measure, cut and bend pipes as needed during installation. In addition, they may install valves, couplings and other elements required for the project. In order to become a pipefitter, you will need to have at least a high school diploma or equivalent certification. It's also important that you get basic instruction on safety procedures before you embark on your career path. Depending on where you live, there may be specialized training programs offered by unions or trade associations that provide additional certifications for aspiring pipefitters. Additionally, many employers prefer candidates who have an apprenticeship or two years of experience in the field before they will hire them full time as a professional pipefitter. There are many different types of projects that someone trained as a pipefitter can work on including residential building sites; construction sites; manufacturing plants; hospitals; power plants; gas stations; government buildings; laboratories; marine installations; refineries; ships; apartment complexes and office towers just to name a few! Once qualified as a professional pipefitter there is often room for advancement into management roles within the company or even starting your own business if desired! Pipefitting isn't just about installing pipes either - it involves problem solving skills as well. As part of their job duties, pipefitters must locate solutions according to applicable codes and regulations set forth by local governments or by national organizations such as OSHA (the Occupational Safety & Health Administration.) Pipefitters may also need to troubleshoot existing systems when something goes wrong like if they are leaking due improper installation or rust buildup over time due humidity levels etc… This type of scenario will require creative solutions on behalf of the pipefitter in order to resolve any issues however this type of situation speaks directly towards one’s knowledge base since problems like these won’t always manifest themselves consistently allowing each individual situation unique while still needing corresponding answers being applied properly once located! When it comes down to it working as a professional pipefitter can open up doors towards having access towards multiple opportunities both professionally & financially speaking regardless whatever line(s) development offers itself up along its way with proper dedication & education being put forth whether its governmental pursuits / private operations both have been known offer good salaries especially when considering long-term investments after all its no surprise why various countries around our world depend heavily upon this specialised craftsmanship cumulatively so why not join today…! Two members of our executive team -- Kristen Chamoun and Alyson Avoglia -- will be featured on WCRN AM 830's "All About the Valley Show" on Nov. 29. The show can be heard HERE

Kristen and Alyson discussed all things TLC with Blackstone Valley Chamber of Commerce President/CEO Jeannie Hebert Our first in a series of "TLC Spotlights" is a talented and popular instructor - Marc Vray.

According to Marc, he reminds students that HVAC is a very broad category with many career avenues. He says, "An HVAC tech needs to be familiar with electrical, sheet metal, fluid mechanics, refrigeration and plumbing fundamentals." When Marc is not helping students launch HVAC careers, he enjoys gardening, music long board skating and skiing We are happy to announce that Christina Mullen has joined the TLC team in the role of financial aid administrator.

In this position, Christina will advise students on the financial aid process and provide information on available programs, procedures, and eligibility. Welcome Christina! New classes starting August 8th! • HVACR • Welding • Power Plant / Steam Engineering Don’t Miss Our Open House on July 7, 20222 at our Oxford campus: 11 Buffum Dam Rd, Oxford, MA 01540 Come tour the facility and learn more about our programs in HVACR, welding and steam engineering. Staff and instructors will be onsite to answer your questions and tell you more about: *Program offerings *Financial aid/ payment options *Job placement assistance *Resources from MassHire & VA *Scheduling - Day and Evening classes RSVP: Please contact [email protected] or call (508) 987-1852 to register. Technology Learning Center of Oxford, MA welcomes Alyson Avoglia as the company’s Director of Admissions and Community Relations.

Alyson holds a B.S. in mathematics from Bentley University and has extensive prior experience in the financial services industry. More recently, Alyson has worked in higher education and grants administration, and is an adult education math instructor. Alyson is excited to contribute to the growth of Technology Learning Center through outreach with local high schools, businesses and community organizations. |

Archives

April 2023

Categories

All

|

|

Technology Learning Center

11 Buffum Dam Rd. Oxford, MA 01540 508-987-1852 |

Serving all of central Massachusetts and beyond. including: Oxford, Worcester, Charlton, Dudley, Southbridge, Douglas, Sutton, Auburn, Leominster, Fitchburg, Webster, northeast CT and much more.

HVAC Training Courses, Oxford, MA I Steam Engineering Online Courses I Trade School, Oxford, MA (Worcester County) © COPYRIGHT 2023 ALL RIGHTS RESERVED.

RSS Feed

RSS Feed